Custom Fabrication

Fabricated parts and components: wide ranging dimensions in any quantity

Whether you need high volume, low volume, or a single prototype, Progressive Systems can deliver.

With the region’s most extensive fabrication capabilities for handling tubing and flat bar stock, as well as lifting and fabricating extremely large components in any quantity, we can produce anything from small parts that fit in the palm of your hand to those that measure up to 570” x 144” x 59” and weigh up to 40 tons.

Custom Fabrication Capabilities

Our custom fabrication capabilities and expertise are always increasing to offer you the latest advancements in fabrication technology and the greatest efficiency in working with a range of materials:

- Carbon steel

- Alloy steel

- Stainless steel

- Titanium

- Aluminum

- Copper

- Brass

- Bronze

- Plastic

Our Customers Have Come to Expect

Extensive part tracking and detailed records assure you of individual attention. Our system tracks all the details at every stage in the process, identifying who worked on which part when, including dates and times. Confidential, extensive records include all prints, specifications, job numbers, change orders and other information to simplify future orders.

To ensure that your concepts can move smoothly into manufacturing, expedite production, and create the results you need with components that fit and work correctly, our professional engineering design services are integrated into the process.

As always, all fabrications from Progressive are proudly made in the USA.

Custom Fabrication

Fabricated parts and components: wide ranging dimensions in any quantity. Whether you need high volume, low volume, or a single prototype, Progressive Systems can deliver.

Forming

Services for straightening, bending, and forming all types. Engineering design systems allow drawings to move straight into process and connected systems enable smooth flow from flat laser to bending.

Cutting

A wide variety of contour cutting equipment allows us to get any job done with precision and perfection.

Machining

Five-axis traveling column machines, Hurco vertical milling centers, and DMG Mori horizontal milling centers provide the versatility to handle your needs from prototypes to high-volume orders.

Part Finishing

In-house automated shot blasting is available along with painting services using all types of liquid-based paints and both manual and automated systems.

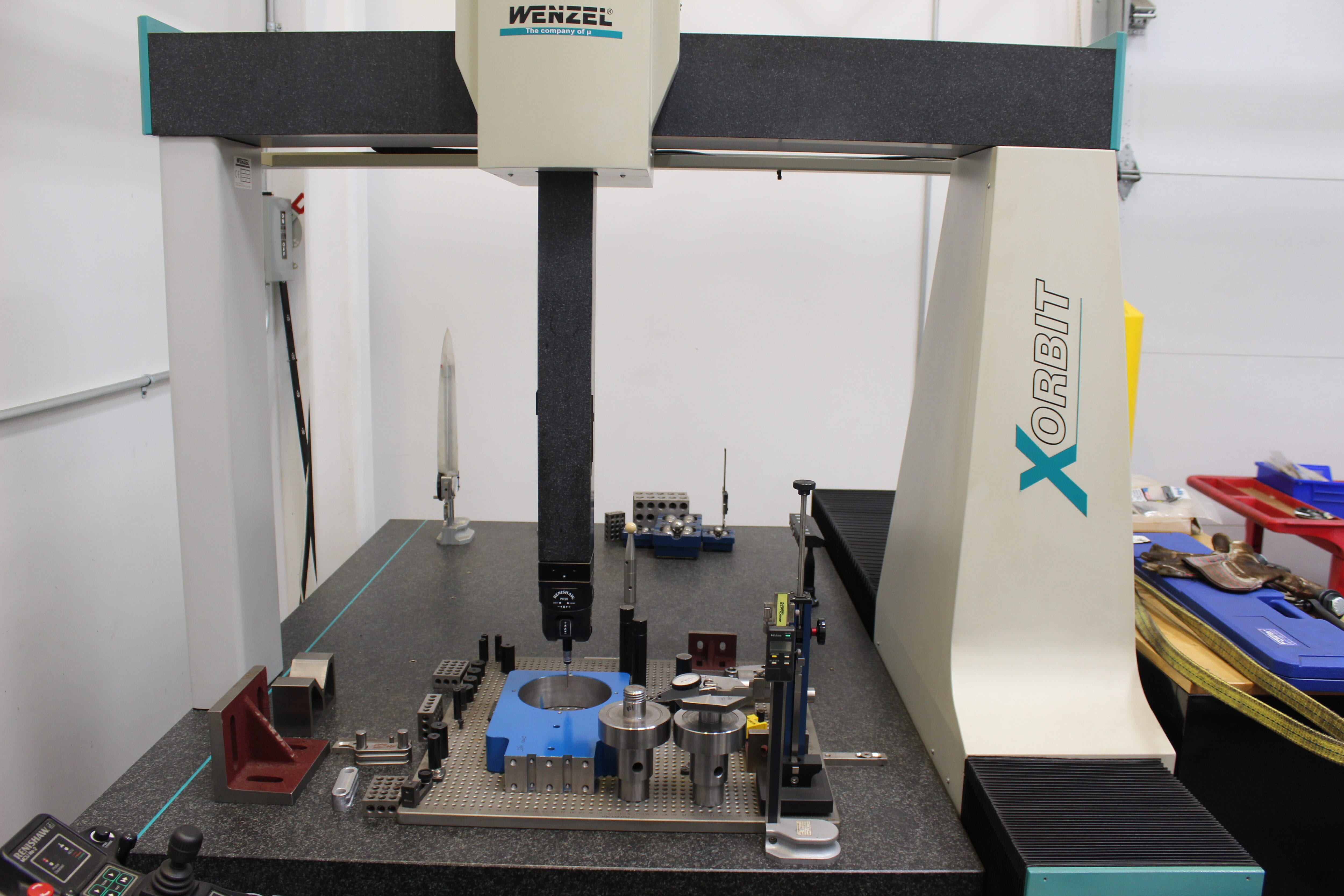

Quality Control

In-house inspection provides documentation of reported inspections for each component throughout the entire process.

Turning

Our lathe department has 2 CNC turning centers and 1 OD grinder to produce perfect rotary work for you.

Welding

Diverse welding techniques, certified to meet safety and quality codes, allow us to work with many different materials, sizes, and quantities, including weldments up to 60’ long and weighing 40 tons.