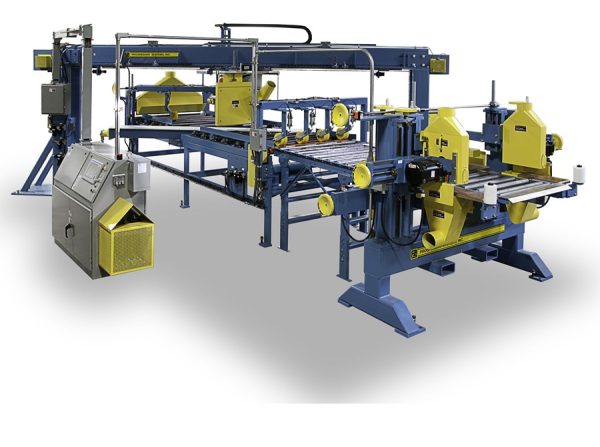

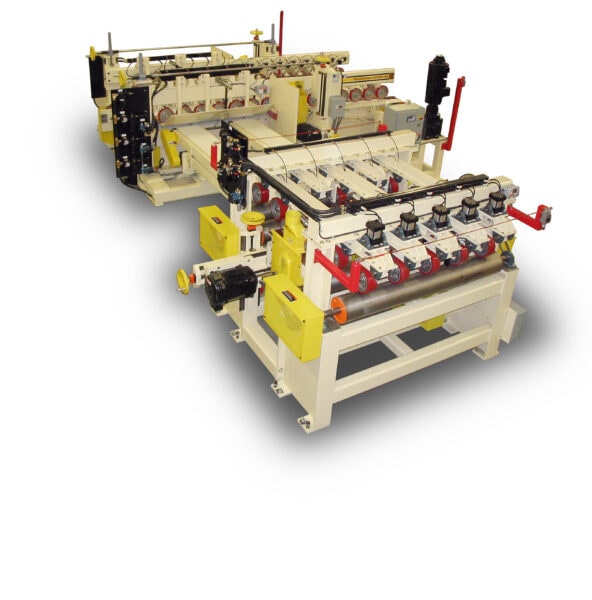

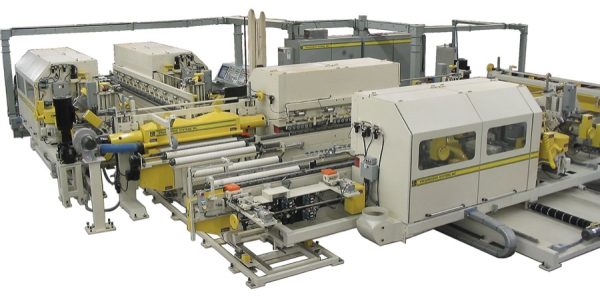

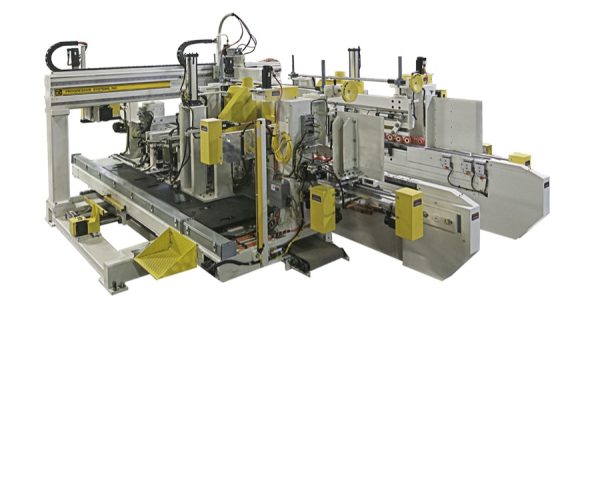

True customization in high-performance industrial machines.

Progressive Systems builds advanced machines of unsurpassed quality and reliability, designed and customized to your specific needs and requirements.

Progressive MAchines

Advanced, High Production Machinery

Progressive Systems has been serving the leading building products manufacturers since 1987 in the Window, Door, Cabinet, Ceiling Tile, Foam, Panel, Plastics, and I-Joist industries with a wide range of customized machines, proudly made in the U.S.A.

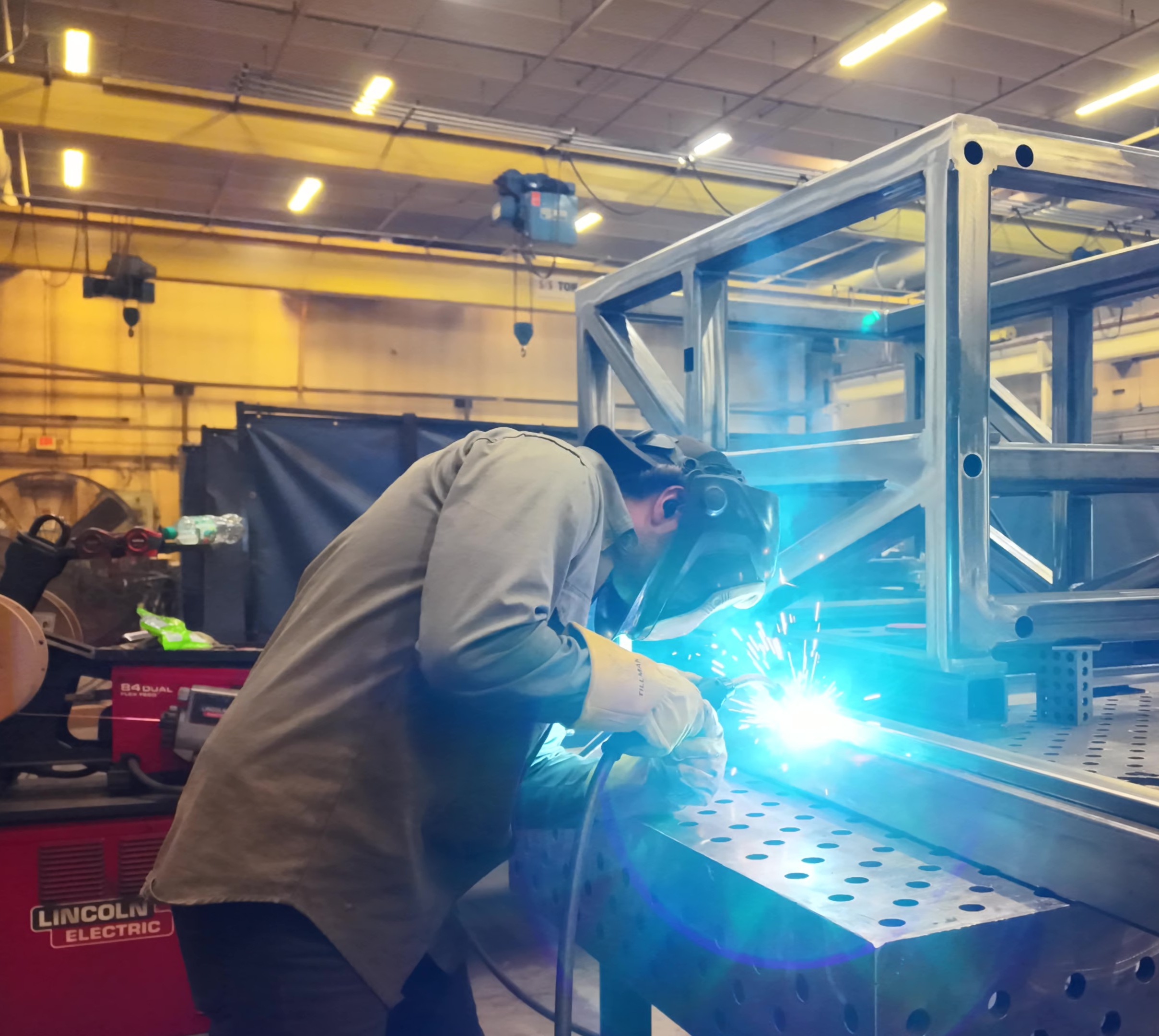

Custom Fabrication

Your Partner in Custom Fabrication

Welding

Diverse welding techniques, certified to meet safety and quality codes, allow us to work with many different materials, sizes, and quantities, including sheet metal, aluminum and weldments up to 60’ long and weighing 40 tons.

- AWS/ANSI D1.1, D1.2, D1.6, ASME

Cutting

A wide variety of contour cutting equipment allows us to get any job done with precision and perfection. Equipment includes:

- 5’x10’ 8kw Flat Laser

- 8’x24’ Plasma Table

- 8’x13’ 5-Axis Water Jet

- 4, Automatic Saws with Auto Indexing and 60-degree Auto Swing

- 12”x12”x30’ Tube Laser w/ beveling head

Machining

Five-axis traveling column machines, Hurco vertical milling centers, and DMG Mori horizontal milling centers provide the versatility to handle your needs from prototypes to high-volume orders, handling parts of any shape in sizes up to 570” x 144” x 59” and weighing up to 40 tons.

Turning

Our lathe department has 2 CNC turning centers and 1 OD grinder to produce perfect rotary work for you. Capabilities in the CNC center include 12-station turret live tooling and machining up to maximum 62.4” length x 23.6” maximum diameter.

Forming

Services for straightening, bending, and forming all types of materials are provided. Forming department machines include:

- 130-Ton brake press with AMNC control for materials up to 122 x 32 x 15in.

- 3 sheet metal rollers

- 65-Ton iron worker

- 600-Ton straightening press

Part Finishing

In-house shot blasting and painting services are available, using all types of liquid-based paints. Additional out-of-house relationships allow us to fulfill all your other coating and finishing needs.

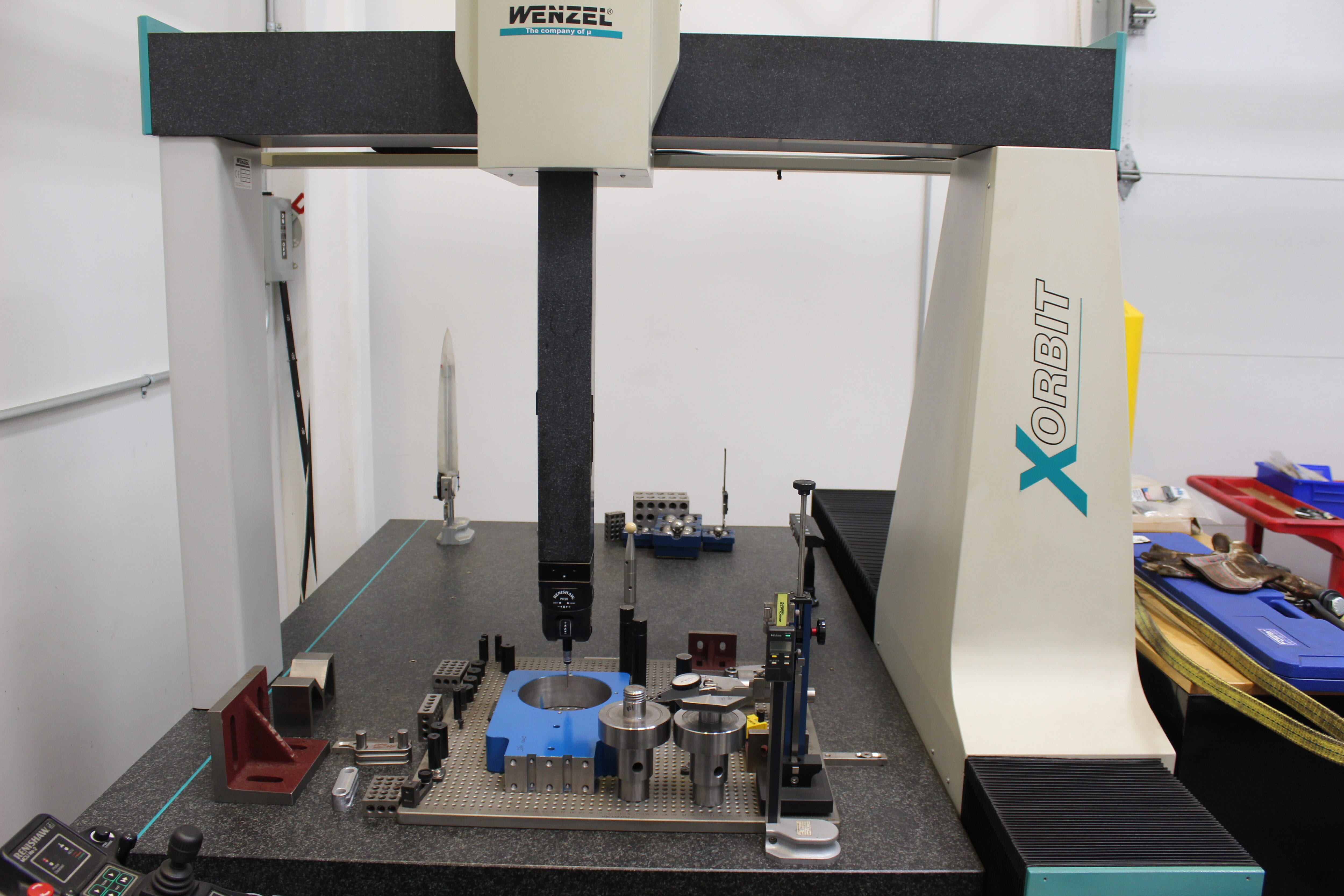

Quality Control

In-house inspection provides documentation of reported inspections for each component throughout the entire process. Full quality control reports, including first article inspection reports, are available upon request.

Who We Are

At heart, we’re engineers who love solving problems and finding new design improvements.

Your success depends on the performance, reliability, and the specialized capabilities of your manufacturing machines. Our mission is to support you in yours, by developing and building customized high-performance, advanced manufacturing machines that are known worldwide for outstanding quality and durability.

Extra capacity in a variety of in-house fabrication services allows us to produce anything from small parts to large format components, up to 45’ by 12’ and up to 40 tons, while assuring you of on-time delivery.

The Progressive Systems Difference

When you get to know how we work, you’ll understand what separates us from the rest.

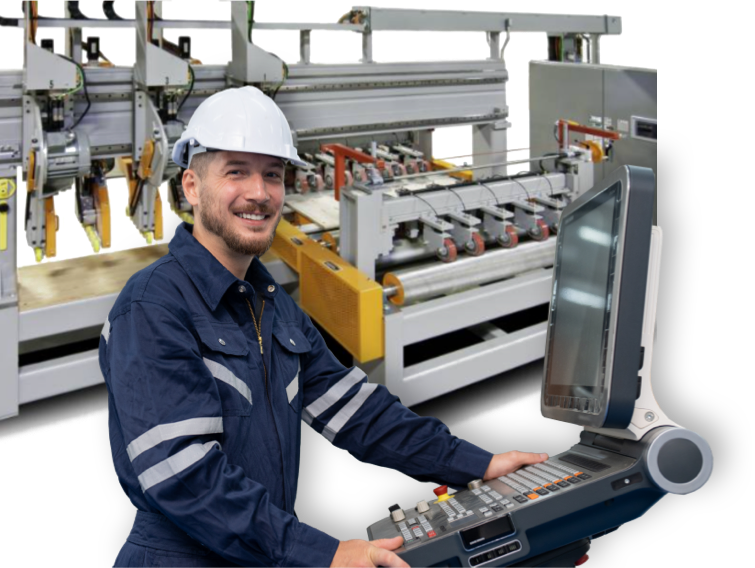

Engineering & Design

Experienced engineers handle designing and concepting in-house based on customer criteria and on-site needs assessments.

Customization

In response to specific customer needs, requirements, and the type of products being produced, drawings and layouts are prepared to reflect customization based on previous designs.

Manufacturing and Testing

Customers are always invited to review progress on their machines during the fabrication and assembly stages. Prior to shipment extensive Factory Acceptance Testing (FAT) is common.

On-Site Implementation

The completed machine is delivered to the site, reassembled and installed by the same team that was involved in the design and building process. And we stay until the machine is in production.

Training, Support, and Maintenance

Support is available on-site or remotely from our world class service department, including the techs who designed, built, and installed the machine.